- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

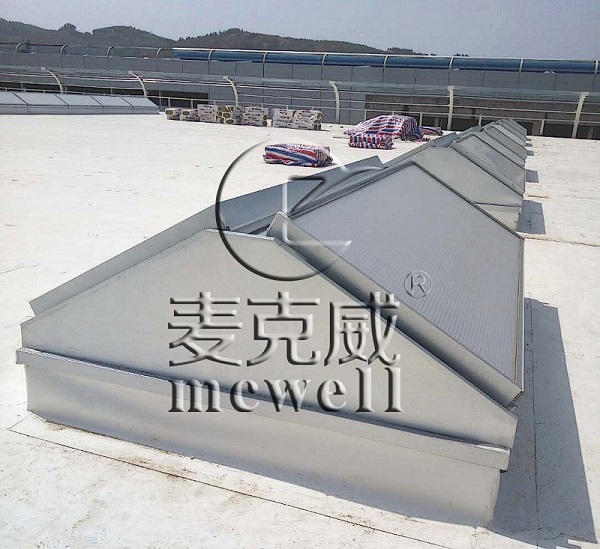

Because of the water leakage, why are electric smoke vent forced to demolished and rebuilt? Mcwell will explain the reasons. In the process of installing electric smoke vents, if the traditional skylight manufacturing process is adopted, the traditional skylight window sash technology not only cannot achieve structural waterproofing at the "corner gap", but must be glued to waterproof, and the daylighting panel also cannot achieve structural waterproofing, so that glue-like substances are used to bond the sash profile around the sash sun board. In the traditional roof vent manufacturing process, the daylight board in the window sash profile is compressed by EPDM rubber strips. Even if the deformation of EPDM reaches the limit value of 3mm or more, the sun board will be pressed tightly, but the EPDM will fatigue and lose its elasticity. There may be stagnant water, which will enter the window sash along the gap between the EPDM and the sun panel. Therefore, a glue-like substance must be used for bonding and waterproofing between the EPDM and the sun panel or between the sun panel and the window sash profile, otherwise water leakage will inevitably occur here. It is unreliable to use colloidal substances (such as silica gel) to bond and waterproof.

There are three main reasons:

1. The smoke ventilator is located on the roof and is directly exposed to wind and sun. As a chemical material, silica gel is exposed to ultraviolet rays from the sun for a long time, and its performance decays quickly. In particular, poor quality colloids will suffer from aging and cracking when exposed to the roof for about half a year.

2. The components bonded by the colloidal substance will expand and contract due to the influence of the environment, and will be displaced. The temperature difference between day and night, the temperature difference in different seasons, and the opening and closing of the roof smoke vent itself will cause repeated displacement of the colloid, which will cause the colloid to crack after a certain period of use, which will cause leakage;

3. The application of colloidal substances is manual operation, and the application quality is affected by factors such as the technical level of the operator, sense of responsibility and attention during operation, and the quality is not stable enough.

The glue material is easy to age and crack and has the hidden danger of water leakage. Repairing the leakage is even more difficult to repair, because the repair method is generally to manually apply the glue material to the outer surface of the gap, so that it is exposed to the sun, ultraviolet rays, wind and rain. Under the environment, the colloid will age more easily.