- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

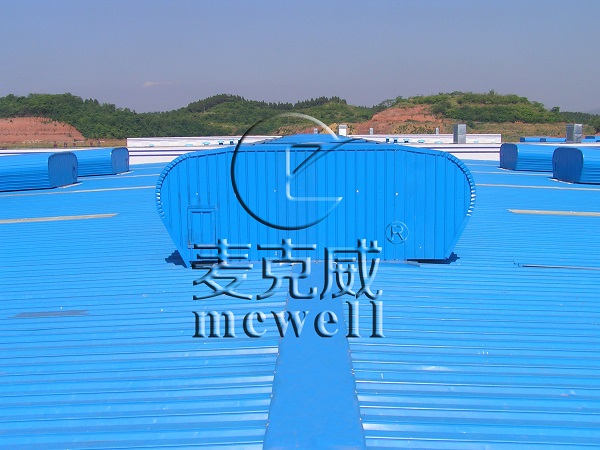

Old-fashioned roof smoke vent has many advantages such as good ventilation performance, light weight, consumable saving, flexible design, reliable quality, convenient installation, and beautiful appearance. The ridge ventilator is widely used for many industrial plants.

During the installation and operation of roof smoke vent on the roof, there are also problems with defects in the manufacturing and installation processes. Old-fashioned steel roof ridge vent is galvanized before they are manufactured, welded and installed, and then the galvanized skeleton connecting rods are welded. This method will definitely leave the hidden danger of corrosion to the welding place; self-tapping screws or rivets are used in the construction site. A large number of perforations can easily damage the anticorrosion ability of the roof ridge vent, and improper handling of the holes can also cause rust problems.

In order to solve this problem, as a professional smoke vents manufacturer, Mcwell upgraded and optimized the manufacturing and installation of ridge ventilator. All main components that require galvanizing should be galvanized after welding to prevent the main components from being corroded; secondly, all parts with screw holes. Holes should be reserved and coated with anti-corrosion paint before the product leaves the factory. The improved natural ventilation skylight not only improves the anti-corrosion ability of the equipment, but also prolongs the service life of the ventilation skylight.