- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

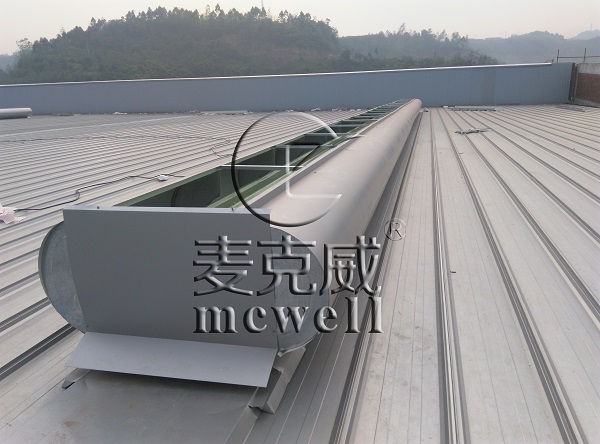

The service life is one of the main performances to measure the quality of roof ridge ventilator, and the factors that affect the service life of steel building ridge vent, in addition to the structural form and specification selection, the anti-corrosion technology from the production process is also an important factor affecting the service life. Mcwell will introduce the anti-corrosion treatment and production process technology.

1. The framework of roof louver vent and small ridge ventilator is hydraulically formed with hot-dip galvanized steel sheets, and the cuts are treated with hot-sprayed zinc sealing and anti-corrosion treatment. The forming adopts 315T liquid press and is integrally formed by special large-scale tooling and moulding;

2. Frame anticorrosion adopts hot-dip galvanizing anticorrosion, welding joints and cuts adopt hot-spray galvanizing anticorrosion to avoid any corrosion weakness; among them, the frame material of the welding frame type large throat ventilation skylight adopts hot-dip galvanized hollow thin-walled square steel, and the amount of galvanized 275g/m2, the welding point adopts hot-spray zinc anti-corrosion technology to ensure no corrosion weakness; 35T hydraulic stretch bending machine is used for bending to ensure that there is no uneven deformation on the inner and outer surfaces, with high bending precision and small deformation;

3. The connection holes of the skeleton components are all drilled in the factory with a special tooling positioning drilling and milling machine, with an accuracy of less than 1mm; on-site bolting is used, and the installation accuracy is within 1cm. Avoid the hidden danger of water leakage and poor appearance quality caused by inaccurate manual positioning of on-site welding and large errors.

4. The color steel plate adopts hot-dip galvanized color-coated steel plate. Mcwell's professional production team and installation team can ensure good protection of the color steel plate coating during the entire production and installation process to avoid corrosion weakness caused by the damage of the color steel plate coating.