- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

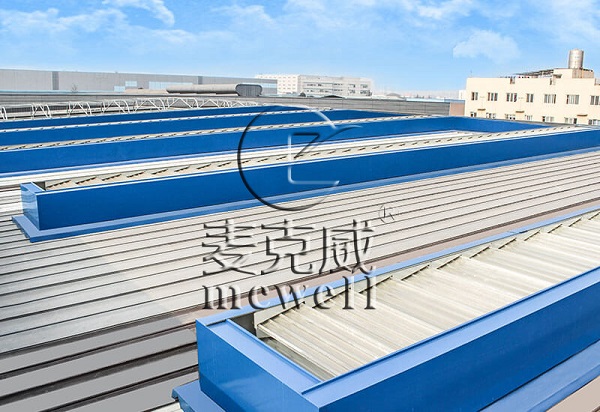

With the continuous upgrading of process technology, the natural vent has also been greatly developed. The arc process of natural roof ventilation's skeleton has also changed. The arc part of the skeleton of the roof smoke vent has three methods: stretch bending, top bending, and roll bending. We use the best stretch bending method. Mcwell's stretch bending machine is specially designed according to the characteristics of natural ventilation system. The working habits of the stretch-bending machine developed are most suitable for the characteristics of the profile frame, because the profile frame is generally a thin-walled rectangular tube or angle steel, and the wall thickness will be selected between 2mm and 4mm.

The feature of Mcwell's stretch bending machine is that the workbench is between the equipment, and the movable arm is used. The two arms hold the two ends of the profile with a force of 200,000 Newtons, so that the profile is tightened, and then leaning against the mold, so that the parts and components of natural ventilator have high precision, the error between different workpieces is between 1mm, and the surface of the parts is smooth and uniform, and the continuity strength is high.