- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

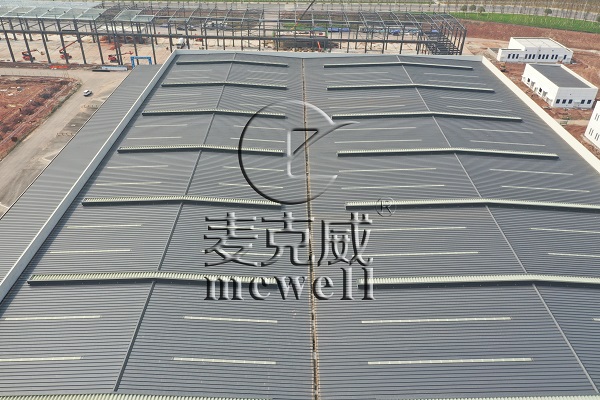

Roof vents are mainly installed on the factory floor for ventilation and smoke exhaust. Regarding the specification requirements for roof louver vent, as a professional smoke vent manufacturer, Mcwell has its own set of guidelines.

1. The design, manufacture, and installation of roof vents must ensure safe, reliable, and continuous operation under the conditions allowed by the equipment.

2. The structure of the roof louver vent must comply with the requirements of the specifications and drawings and atlases and have a reasonable layout, smooth air flow, no dead corners for ventilation, and low air flow resistance; the windshield layout is reasonable, with high strength and good windshield It can effectively prevent the outdoor air from backflowing; and it must have reliable measures to prevent rain and snow infiltration to ensure that the natural ventilation system does not penetrate the rain and snow into the room under any weather conditions.

3. The roof louver vent body is required to be firm, safe and reliable, able to withstand the local wind load, snow load and ash load, and does not affect the normal operation of the natural roof ventilation. At the same time, the roof vents should meet the relevant local seismic regulations. The selection and determination of wind load value, snow load and ash load value shall be carried out in accordance with the relevant regulations in GB50009-2001 "Building Structure Load Code".

4. The low-profile ventilator should take anti-corrosion measures. The steel components should be pickled, neutralized, phosphatized, passivated, and dried, and then hot-dip galvanized. The inside and outside of the square pipe must be hot-dip galvanized. Hot-dip galvanized steel components are sprayed with zinc after slag removal. The zinc layer is in accordance with the national standard: GB/T 12754-2006 (7.2.3), and the amount of galvanizing is 275g/m2.

5. After installation, the outer surface of the roof louver vent shall not exceed the range of the lightning rod of the building.