- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

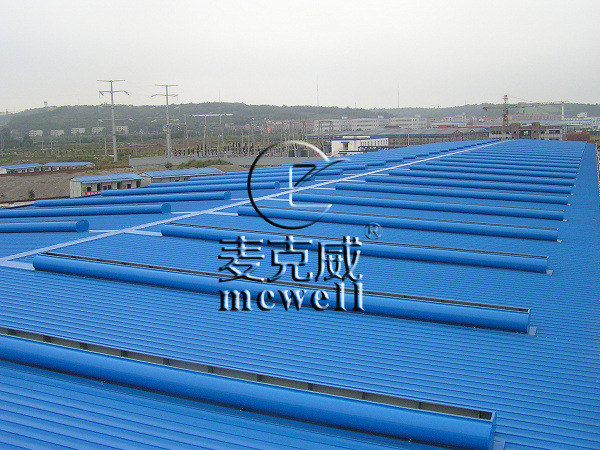

Roof smoke vent is generally installed on the factory's roof, which can realize the functions of ventilation, smoke exhaust and daylighting. It is an indispensable roofing equipment and facility for modern steel structure factory buildings. The roof smoke vent skylights installed with the opening and closing valve plate is called the opening and closing ventilation skylight, and the opposite is the opening natural ventilation system. The smoke vents are controlled by installing electric actuators to open and close the electric valve plate. Therefore, the electric actuators need to meet the technical requirements of the project during production.

1. The opening and closing valve plate of the opening and closing roof smoke vent should have good rigidity, anti-drifting snow function and air flow performance.

2. The electric valve plate is controlled by remote control for switch operation. The electric ventilation, lighting, and smoke exhaust skylight valve plate and transmission mechanism are flexible and reliable in operation.

3. After the electric valve plate is closed, it can withstand the influence of heat pressure and is well sealed, and has a certain heat preservation performance.

4. The electric valve plate of the smoke vent skylights does not block the air outlet area when it is opened, and it is more sealed when it is closed.

5. The valve plate transmission mechanism can work normally under high temperature and high humidity environment. The valve plate cannot be opened or closed due to corrosion and thermal expansion.

6. The electric actuator has certain high temperature resistance and can withstand the highest temperature in the room.