- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

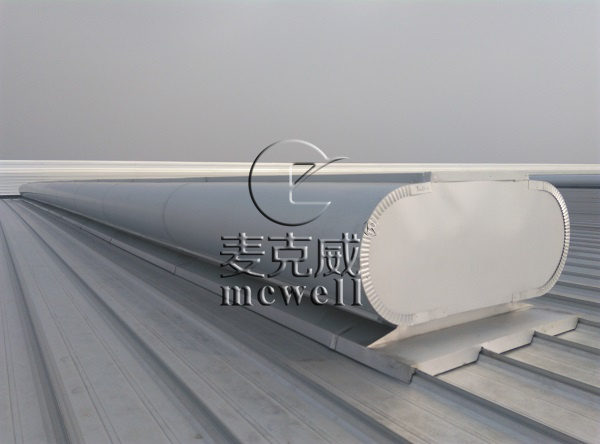

Steel roof ridge vent, with beautiful appearance and smooth lines, is roof ventilation equipment often used in modern industrial plants. The skeleton is a key part in the production of ridge ventilator, which supports the entire roof ridge vent.

The frame of the steel roof ridge vent is designed as a circular arc structure, which guarantees the strength requirements of the ridge ventilator itself. In terms of material selection, hot-dip galvanized open-web steel is selected for the streamlined smoke vents frame. The streamlined smoke vents are installed on the factory's roof, and they are exposed to the sun and rain for a long time. The advantages of using hot-dip galvanized open-web steel are that it does not rust and has strong rigidity, ensuring the toughness and strength of the skeleton and the service life. After the hot-dip galvanized open-web steel material is transported to the production and processing plant, professional workers will cut it according to the size of the throat of the streamlined natural ventilator. Since the skeleton of the ridge ventilator is generally large, the structure of the skeleton is not complete at the beginning. Workers need to split the skeleton structure, that is, the straight lines are grouped into one pile for processing, and the curved ones are grouped into one pile for processing. According to the given size of the steel roof ridge vent structure drawing, the steel is measured, and the cutting machine is used for cutting, and the cut hot-dip galvanized open-web steel material is cut and angled to facilitate subsequent welding.

The arc part of the ridge ventilator frame needs to use the plasticity of the hot-dip galvanized open-web steel material to make the steel into a circular arc structure by using the plasticity of the hot-dip galvanized open-web steel material to make the steel an arc-shaped structure. Make appropriate corrections to the angle of the plate until the shape of the same plate is the same as the processed material. After cutting and processing many steels, the skeleton needs to be welded as a whole. When welding, it should be noted that you must wear a protective mask to prevent the light from damaging your eyes during welding.

When the skeleton is welded as a whole, the basic shape of the main body is already present, but due to the different heights of the welded joints, and at the same time, in order to eliminate some of the safety impacts caused by these protrusions on the skeleton, the welded joints need to be smoothed. The speed of the correction must be uniform to make the welding joint and the material smooth. After rest, paint should be applied to the trimmed position to prevent rusting of the welded joints. After all the work is completed, the skeleton can be painted. The main purpose of painting is to prevent corrosion, but also to make the skeleton look more beautiful.