- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

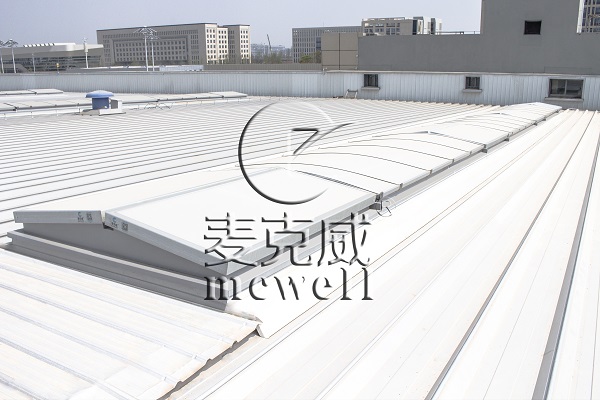

According to the installation position, smoke vent rooflight can be divided into roof smoke ventilator and side wall roof smoke vent. Electric lighting and smoke exhaust ventilator which is installed on the roof will be directly impacted by outdoor wind and snow loads and rain. Therefore, the waterproof performance of roof automatic opening vent is an issue that manufacturers should focus on.

1. Traditional technology: the hidden danger of water leakage that cannot be completely solved by the "corner gap"

At present, the traditional method of window sash profiles of many electric smoke vent rooflight manufacturers is to combine four independent broken bridge aluminum profiles. The "corner gap" connects the room. The interior of the corner gap is glued with silicone, and the silicone overflows the gap. After the silica gel cracks and ages, rain water may enter the room through the "corner gap". There is a huge hidden danger of water leakage in this gap.

2. No nail, no glue, internal drainage and waterproof technology

The nail-free and glue-free structure waterproof technology of Mcwell's smoke exhaust ventilator adopts the integral closed-loop internal flooding. The inner profile of the broken bridge aluminum profile is an integrated structure. The integral flooding plate separates the indoor and the outdoor. The water board is isolated and discharged outside. The hidden danger of water leakage caused by the "corner gap" of traditional fire smoke exhaust skylights is eliminated.

The patented technology of “nail-free and glue-free waterproof structure” automatic opening vent of Mcwell ventilation equipment has been widely used in industrial plants of all walks of life, replacing traditional silicone waterproof technology and opening a new chapter in waterproof technology in the ventilation industry.