- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

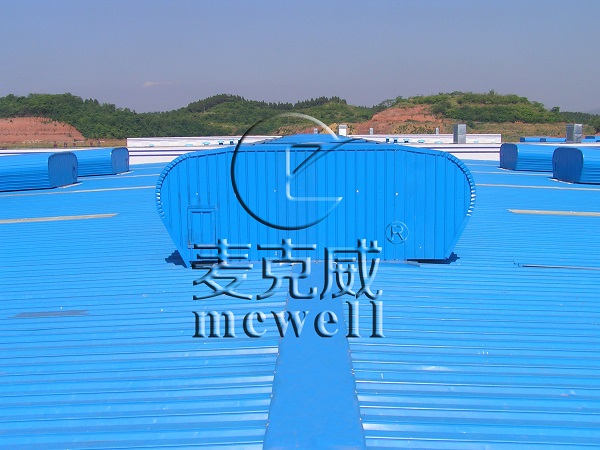

Opening And Closing Ridge Ventilator plays an important role in the environmental protection of industrial plants. As lighting and ventilation equipment installed on the factory's, they can not only provide natural lighting for the workshops, but also ventilate and exhaust smoke to purify the air, providing a good interior for the factory.

1. Features

Opening and closing ridge ventilator is installed on the ridge of the factory roof. Generally, the throat ventilation size is larger, usually 1500mm-9000mm, so the smoke and ventilation performance is good. It can efficiently realize ventilation and fire-fighting smoke exhaust for high-temperature and high-heat workshops through the difference in indoor and outdoor temperature and wind pressure, ensuring the air quality of the workshops.

2. Type

According to the different shapes, it can be divided into MCW1 and MCW2 thin electric smoke exhaust ventilator, MCW4 and MCW5 streamlined natural ventilator. At the same time, it can be divided into open and closed roof ridge lighting and ventilation skylights and thermal insulation according to whether the plant has lighting requirements. Type electric roof ventilator, the former’s rain-proof board is made of FRP daylighting board with high light transmittance, and the latter’s rain-proof board is made of color steel plate.

3. Control method

The opening and closing smoke vents are equipped with an electric valve plate, which can be linked with fire fighting to realize the function of fire fighting and smoke exhaust. At the same time, the ventilation and smoke discharge of the finished daylighting and exhausting skylight can be controlled by adjusting the opening and closing of the valve plate. In winter, closing the valve plate can also realize the insulation function of the workshop.