- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

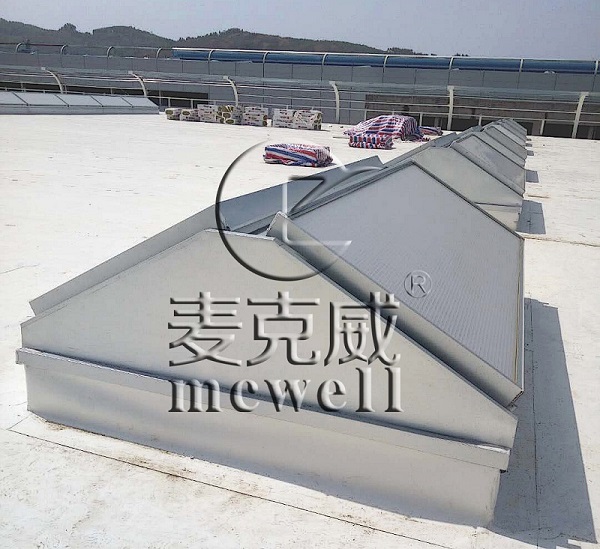

The installation of smoke vent skylights in steel structure workshops is usually to achieve ventilation and exhaust smoke, which ensure good air quality indoor, and provide a better working environment for workers in the first-line production workshop. Some users do not know the specific performance of the smoke ventilator, so the followings are detailed description of the performance and use requirements of the ventilation and smoke exhaust skylights.

1. The materials and performance of the roof smoke ventilators

The airtightness, watertightness, and wind pressure resistance of the smoke hatch skylight need to comply with the international standard T7106-2008, the lighting performance needs to comply with the international standard T11976-2002, and the thermal insulation performance needs to comply with the international standard T8484-2008.

2. Description of the construction profile parameters of the roof vents

The profile construction of the smoke vent system is mainly made of 0.6 thickness color steel plate cold-formed, and the interior is mainly filled with polyurethane foam material, the thermal conductivity is ≤0.025W/m*K, and the profile members of the window are connected by self-tapping screws. The sealing material uses low temperature resistant EPDM rubber material sealing strip.

3. Aluminum alloy profiles for automatic roof vents

The window sashes of the smoke vent is mainly made of aluminum window profiles, with a yield strength of 110N/mm², a tensile strength of 160N/mm², a hardness of HV≥58, and a wall thickness of 1.4mm.

4. Material selection of daylighting panels for smoke vent windows

Generally speaking, the material selection of daylighting panels for roof mounted exhaust vent in steel structure workshops is wide, including safety glass, sun panels, FRP daylighting panels, and so on. When choose the panels, it is necessary to indicate which type of lighting material is used.

1. The materials and performance of the roof smoke ventilators