- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

In order to make industrial factories run stably and efficiently, many factories will be designed to install electric smoke exhaust ventilator. Today, we will learn about it in detail from four aspects.

1. Working principle

When the sash of the smoke exhaust ventilator is opened, it uses the wind pressure difference and thermal pressure difference inside and outside the factory building to inhale clean air outside the factory building, and discharge the waste heat exhaust gas in the factory building, which is essentially a natural ventilation smoke exhaust equipment.

2. Classification

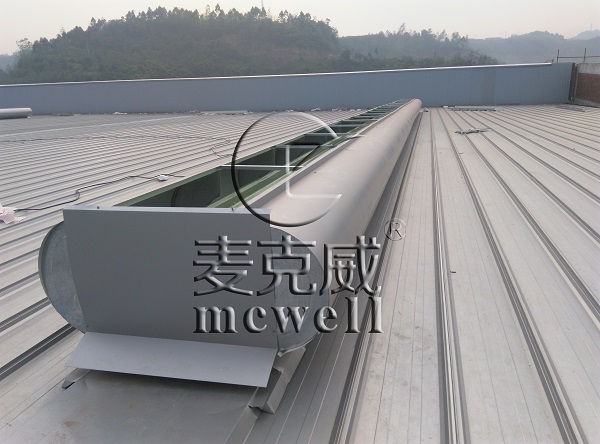

In order to meet the needs of different workshops, electric smoke ventilator also has different window types. Specifically, it can be divided into three categories, namely triangular smoke exhaust skylight, C2T one-shaped electric lighting smoke exhaust skylight and circular arch skylight. The specific type of fire smoke exhaust skylight selected depends on the actual situation of the factory building.

3. Function

The electric smoke vent is made of high-quality light-transmitting sheet, so it has a good natural lighting function. The triangular downward-opening electric lighting and smoke exhaust window and the side-opening circular arch electric lighting and smoke exhaust skylight can meet the daily ventilation needs of the workshop and have good rainproof performance; the in-line electric lighting and smoke exhaust skylight and C3ST The dome-type electric lighting and smoke exhaust skylight (upper opening type) window sash opens upwards, which has good fire-fighting and smoke-exhausting performance.

4. Application areas

Structural workshop ventilation skylights can be installed and used in light industry, warehousing and logistics, automobile manufacturing, rail transit, aerospace and other industries, with a wide range of applications and high popularity.