- info@mcwell.cc

- +86 13881905158

- Quick Enquiry

Under the vigorous promotion of the "low carbon, energy saving and environmental protection" policy, and under the strict requirements of the new consumer regulations, newly built industrial plants have installed fire-fighting and smoke-exhaust skylights. Today we will come to a comprehensive understanding of smoke exhaust ventilator.

1. Fire and smoke exhaust

The fire-fighting smoke exhaust ventilator has a fire-fighting linkage function. When fire occurs, the skylight electric control box can immediately receive the fire-fighting signal, and quickly control the electric push rod to open the window sash to discharge the indoor smoke and heat, and create a clearly visible escape channel for rescue. Buying more time can effectively reduce casualties and property losses.

2. Lighting

Window sashes made of FRP lighting panels, hollow sunlight panels, and hollow laminated glass ensure that the smoke ventilator have good lighting performance, which can improve the natural lighting rate for workshops and effectively save the use of lighting equipment.

3. Thermal insulation

The roof lighting and smoke vent made of broken bridge aluminum profiles has good thermal insulation performance, and at the same time can effectively prevent the generation of condensed water.

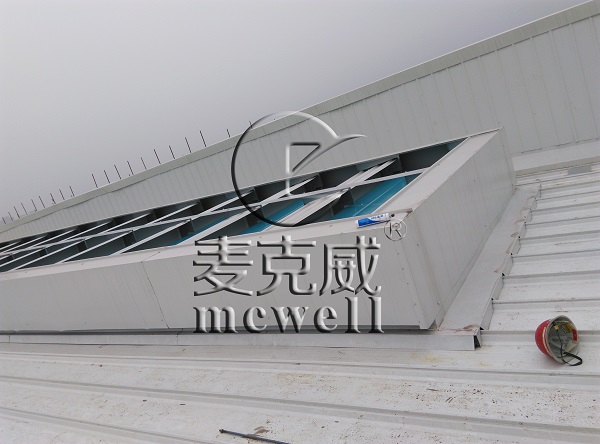

Four, multiple models

There are many models of fire-fighting linkage smoke exhaust skylights: straight-line skylights, triangular electric smoke exhaust skylights, and round arch skylights, which can meet the different functional needs of workshops and adapt to the production and operation of industrial plants.

The fire-fighting smoke exhaust skylight can meet the functional requirements of the daily operation of the workshop, and at the same time can ensure the fire safety. It is an indispensable supporting equipment for industrial plants.